OPINION

Washington state is the clear choice for building the 777X

By DAVID GROVES

EVERETT, Wash. (Oct. 31, 2013) — Perhaps as soon as next month, The Boeing Co. will announce where it will assemble the 777X, a stretched version of the 777 wide-body twin-engined jet built here in Everett. The company is expected to formally launch the 777X program at the Dubai Air Show that opens Nov. 17, but may not announce whether it intends to build it in Washington state or South Carolina until some time later.

Yesterday, Boeing issued a cagily worded memo announcing that “much of the detailed design” work for the 777X will be done at the company’s engineering facilities in Russia and five U.S. locations other than Washington, ominously adding: “However, at this time, no decisions have been made about 777X design or build in Puget Sound.”

As one industry analyst suggests, it “could well be another of Boeing’s masterful chess games to extract incentives from Washington, South Carolina or the undisclosed state.”

It’s time for a 777X reality check.

It’s time for a 777X reality check.

If you are a Boeing shareholder or customer, this decision will be the true test of whether the company has learned anything from the 787 debacle. Will the 777X announcement signal Boeing’s renewed focus on delivering a quality reliable product on time? Or will it signal another risky ideological experiment in building a jet on the cheap?

The truth is that Boeing’s troubled South Carolina 787 assembly line continues to underperform and Washington’s workforce continues to pick up its considerable slack. The truth is that Washington’s workforce not only bailed out management from its costly 787 outsourcing experiment, it is the commercial jet production here in Washington that has driven company profits to record levels as defense cuts and 787 costs have dragged on Boeing’s bottom line. In fact, an argument could be made that Washington’s workforce has saved the jobs of the Boeing executives about to make this 777X decision.

But at its most fundamental level, the impending 777X decision will answer the question of whether Boeing executives still — STILL! — believe that it doesn’t matter who inserts Tab A into Slot B, it only matters what they cost. Or if they belong a union.

HERE WE GO AGAIN?

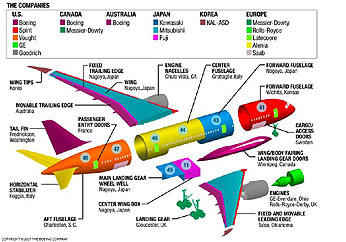

Ten years ago, Boeing management in Chicago devised a new business model intended to cut costs and reduce its employee count by outsourcing the design and manufacture of 787 parts all over the planet. Chicago decided it didn’t have to “bet the company” on 787 development, and instead it would have suppliers spend hundreds of millions of their own dollars to design and produce the parts.

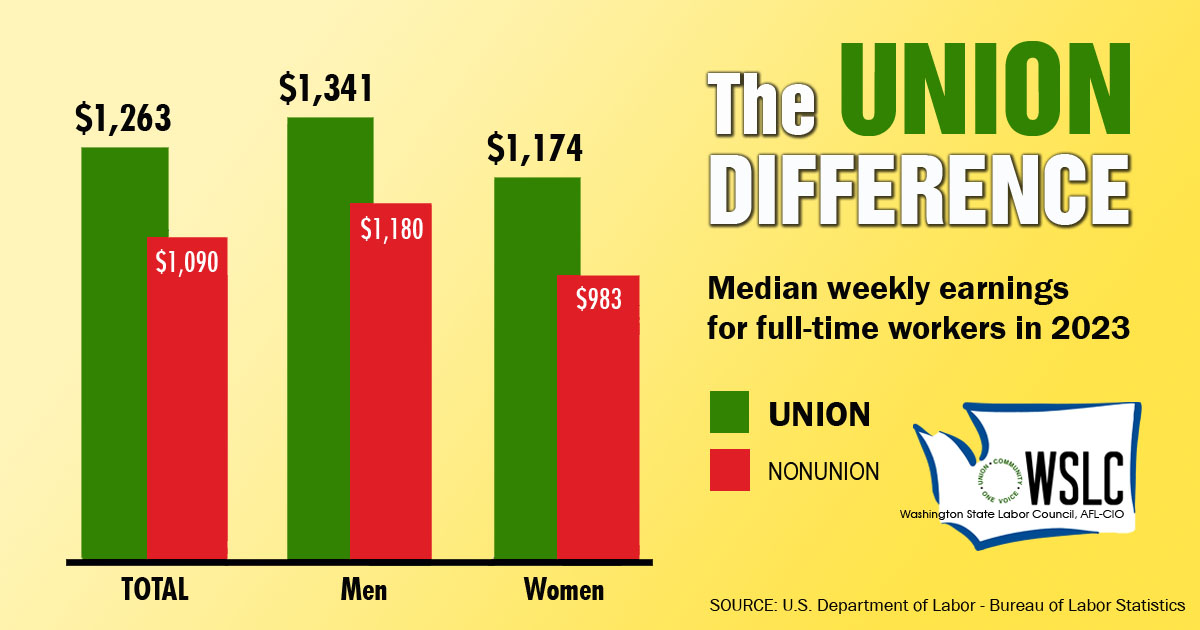

The bottom line was the bottom line. Just to secure the final assembly jobs, Washington state gave Boeing a tax break so massive that the World Trade Organization deemed it an illegal subsidy. So why pay a bunch of expensive unionized Boeing machinists and engineers to do all that design and manufacturing work when you can get somebody else to do it?

The bottom line was the bottom line. Just to secure the final assembly jobs, Washington state gave Boeing a tax break so massive that the World Trade Organization deemed it an illegal subsidy. So why pay a bunch of expensive unionized Boeing machinists and engineers to do all that design and manufacturing work when you can get somebody else to do it?

Genius, right?

As it turned out, not so much. The pieces didn’t fit together. And some of them just weren’t usable.

The price the company paid for Chicago’s 787-on-the-cheap experiment is difficult to quantify. A “conservative” estimate by The Seattle Times was a staggering $32 billion cost to develop the 787 and to rebuild already-assembled but unusable jets. The Wall Street Journal has estimated that Boeing will have to deliver 1,100 of the 787s before the program will return a profit. To date, it’s delivered fewer than 100. The more than three-year delay in the 787’s rollout also harmed its competitive position versus Airbus because it has significantly delayed Boeing’s entire jet development schedule, including the 777X program.

In the end, Boeing had to call on its unionized workforce to clean up the mess by insourcing much of the work back to Washington state. Chicago suddenly needed “our world-class engineers, machinists and technicians to fix the dog’s breakfast their outsourcing made of the Dreamliner,” as Seattle Times business columnist Jon Talton wrote.

WHY BOEING IS IN SOUTH CAROLINA

And let’s not forget why Boeing is in South Carolina in the first place. It was because a key supplier for the outsourced 787 — the Charleston, S.C.-based Vought Industries — failed its mission so profoundly that it jeopardized the entire 787 program and Boeing was forced to buy the company in 2008 to fix the problem. That was about $1 billion of that unexpected $32 billion in costs.

Later in 2008, the Boeing Machinists went on strike for eight weeks. The union’s key issue, not surprisingly, was Boeing’s outsourcing of their jobs.

So in 2009, Chicago decided to expand its new S.C. plant into a full 787 assembly line to create a counter-weight to the company’s Puget Sound area plants. The company admitted — too publicly, as it turned out — that the S.C. expansion was in retaliation for the Boeing Machinists strike and they celebrated the fact that their new plant is in a state that proactively discourages unionization through a right-to-work law. Now the company is buying up land for a planned expansion there, leading some analysts to proclaim that Boeing will gradually shift more and more Boeing jobs from its unionized Washington operations to anti-union South Carolina.

So in 2009, Chicago decided to expand its new S.C. plant into a full 787 assembly line to create a counter-weight to the company’s Puget Sound area plants. The company admitted — too publicly, as it turned out — that the S.C. expansion was in retaliation for the Boeing Machinists strike and they celebrated the fact that their new plant is in a state that proactively discourages unionization through a right-to-work law. Now the company is buying up land for a planned expansion there, leading some analysts to proclaim that Boeing will gradually shift more and more Boeing jobs from its unionized Washington operations to anti-union South Carolina.

But again, as with the failed outsourcing experiment, the underlying assumption with this cost-cutting union-avoidance strategy is that it makes no difference who is building these planes in terms of quality, efficiency and productivity, it only matters what that labor costs.

Unfortunately for Chicago, the evidence continues to mount that this is a faulty assumption.

ALL PLANTS ARE NOT EQUAL

There are two 787 assembly lines in Everett — one permanent and one temporary (we’re told) — and the one in North Charleston. Boeing has said its goal is to produce 10 787s per month by the end of 2013 and has said the South Carolina line would produce three of those 10 per month. But Boeing publicly acknowledged this summer that the North Charleston plant wasn’t going to hit that target.

It’s worse than that. Sources have told The Stand that the North Charleston production rate for new aircraft assembly is currently just three-quarters of a jet per month, and that a significant percentage of the Charleston-assembled 787s had issues that required repairs in Everett before they were delivered to customers.

All Boeing has said is that they are increasing Everett’s already accelerated 787 production rate to pick up South Carolina’s slack.

There is absolutely no question that the highly trained, experienced Boeing workforce in Washington state is operating more efficiently and effectively.

WASHINGTON IS THE CLEAR CHOICE

In addition to having an experienced and proficient workforce, there are obvious cost advantages for building the 777X in Washington state. The company has an existing 777 supplier network, existing buildings and related infrastructure, a new robotic paint shop already large enough to accommodate the 777X wing, room at Everett’s Paine Field for 777X wing production, and state and local governments that are already proposing a fresh bouquet of incentives, including a 16-year extension of those tax breaks the WTO says are too damn high.

In terms of business costs, many national studies — including the U.S. Chamber of Commerce’s — say Washington has a better business climate than South Carolina. For example, both of the definitive state-by-state comparisons of employer costs for workers’ compensation (here and here) say Washington is less expensive than South Carolina.

Is the only item in the “con” column for Everett that it’s unionized? Are the machinists and engineers here earning wages and benefits so much higher than their counterparts in South Carolina that all of Washington’s cost savings and tax breaks, and the unionized workforce’s higher productivity and proven reliability, don’t outweigh this? (And, um, do Boeing’s South Carolina employees know this?)

That’s the reward Boeing management may soon give to the men and women who absolutely rescued the company from their 787 mistakes. And continue to rescue, as you read this column.

That’s the reward Boeing management may soon give to the men and women who absolutely rescued the company from their 787 mistakes. And continue to rescue, as you read this column.

“Thanks for everything, but after all, you did go on strike when we tried to outsource your jobs, soooo…”

Scott Hamilton of the aerospace consulting firm Leeham Co. says his sources told him that the Boeing Commercial Airplanes division wants to build the 777X in Everett, but CEO Jim McNerney is the “wild card” who generally favors South Carolina over Washington simply because it’s not unionized.

Let’s hope that rational heads prevail in Chicago.

In the meantime, the company better not drag out its state-vs.-state game of “Show Me the Carrots” for too long. After Boeing lost a major Japanese airline customer earlier this month, aviation analyst Richard Aboulafia said it was a clear message to Boeing that it needs to stop dragging its feet on the 777X and for Boeing to ensure that it won’t have the same problems the 787 has had.

Announcing that Washington state will get the 777X work will provide customers and shareholders that assurance.

David Groves is Editor of The Stand. He can be reached at david.groves@thestand.org.